Difference between revisions of "Mark2 Assembly"

| Line 226: | Line 226: | ||

There is a nut trap inside each of the cylindrical cut-outs for the smooth-rods. Insert a nut into each one, oriented so that a bolt can pass through it through the hole in the printed part. If the nut is incorrectly oriented, try tapping the part gently - if you're lucky, the nut should tend towards being correctly oriented. If you're unlucky, you might need to remove the nut and drop try to place it again. Once in the correct orientation, screw the bolt into (but not yet extending out of) the nut, as shown. | There is a nut trap inside each of the cylindrical cut-outs for the smooth-rods. Insert a nut into each one, oriented so that a bolt can pass through it through the hole in the printed part. If the nut is incorrectly oriented, try tapping the part gently - if you're lucky, the nut should tend towards being correctly oriented. If you're unlucky, you might need to remove the nut and drop try to place it again. Once in the correct orientation, screw the bolt into (but not yet extending out of) the nut, as shown. | ||

==== Motor Pulley ==== | |||

[[File:X-motor-pulley.PNG|thumb|{{ThumbSize}}|X-Motor Pulley]] | |||

Requires: | |||

* {{Qty|1|NEMA 17 Stepper Motor}} | |||

* {{Qty|1|GT2 Pulley}} | |||

Install the GT2 pulley onto the stepper motor shaft, spaced as shown. Take care that one of the grub screws aligns with the flat of the motor shaft to ensure a good grip. | |||

==== Motor Installation ==== | |||

[[File:X-motor-motor.PNG|thumb|{{ThumbSize}}|X-Motor Stepper Installation]] | |||

Requires: | |||

* {{Qty|1|NEMA 17 Stepper Motor}} | |||

* {{Qty|3|{{Bolt|M3|20}}}} | |||

Fasten the stepper motor in place as shown. It is easier later to wire the motor with the cable connector oriented downwards. | |||

==== Endstop ==== | ==== Endstop ==== | ||

Revision as of 00:33, 1 December 2015

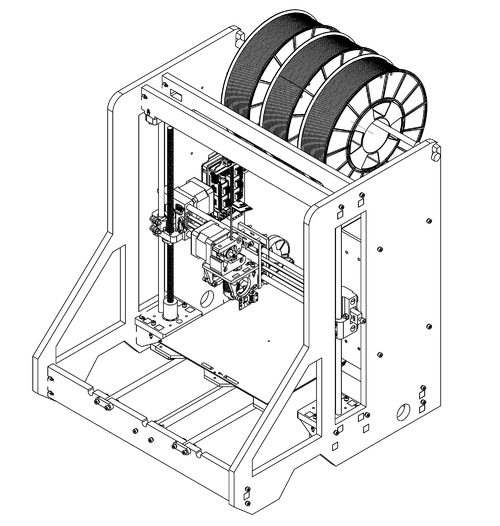

Getting Started

First things first - thanks for your support! We appreciate your business, and hope that your experience with our printer is a happy and productive one! If you get stuck, and you can't find the answer you need here, feel free to contact us - we'd be happy to help!

To get started, find yourself a nice, open space to work - a table or workbench is ideal. Open up your kit, and grab all of the included parts out and arrange them nearby. After unboxing everything, take the time to compare the included bill-of-materials (BOM) against the contents of the kit. We work hard to make sure everything you need is in the box, but it's good to double check. Many components come inside one of the labelled boxes - if you're having trouble finding a part, check the BOM to find out which box it should be in.

Once you've got that sorted, it's time to get the acrylic parts ready. You'll want to peel the protective paper coating off of the acrylic before putting the printer together. Using a sharp knife or fine pair of tweezers can make it easier to separate the paper from the acrylic. This can take a little while - whether you want to do it all in one go, or bit-by-bit as you assemble the printer is up to you.

General Notes

Here are a few important notes before we proceed with assembly.

Our acrylic frame is as sturdy as they come, but over-tightened screws can still cause damage. Spring washers significantly reduce the chance of damage, and ensure that bolts stay tight long after assembly. Be sure to use one of the included spring-washers on every bolt that comes into contact with the acrylic frame.

Test all linear bearings before using them by running them along one of the included smooth rods - sometimes they have too much grease applied internally, which can make them resistant at first. If this is the case, rinse the bearing under water briefly, dry as best as possible, and try running along the smooth rod again. Over time the grease will spread through the bearing, making them smoother - running the bearing along the rod a few times may help. Generally, after rinsing and some motion, the bearings should be smooth enough to move under gravity when the rod is held vertically.

Many of the images on this page are animated - click on them to see the animation.

Main Frame Assembly

Z Motor Brackets

Requires:

- 4x z-motor-brace

- 2x z-motor-bracket

- 4x M3x20mm Bolt

- 4x M3 Spring Washer

- 4x M3 Hex Nut

Assemble both Z Motor Brackets as shown in the image.

Side Panels

Requires:

- 2x Assembled Z Bracket

- 4x M3x20mm Bolt

- 4x M3 Spring Washer

- 4x M3 Hex Nut

Install the brackets onto the side panels. Take note that the side panel with the mounting holes for the controller goes on the left, and the panel with the mounting holes for the PSU on the right.

Front Panels

Requires:

- 2x Assembled Side Panel

- 1x y-axis-front

- 1x y-axis-rear

- 1x frame-top-bar-front

- 1x frame-top-bar-rear

- 12x M3x20mm Bolt

- 12x M3 Spring Washer

- 12x M3 Hex Nut

Insert the four horizontal panels into the slots on one of the side panels. It may be helpful to lay the side panel flat so everything stays in place.

Take care in the orientation of the y-axis-front and y-axis-rear panels - they are not symmetrical. When viewed from the front, the y-axis-front panel should have a notch on the right-most screw hole (pictured below). The y-axis-rear panel should have the rectangular endstop cutouts to the left.

One of the z-top-panels has a cutout for wiring - this panel should be placed nearer the back of the printer, behind the other z-top-panel. If you're using the LCD add-on, swap the front-most z-top-panel out for the LCD cutout. The rear panel should have a cut-out for running cables to the LCD.

Place the remaining side panel on top of the horizontal panels, and fasten it in place. There are 6 bolts to install on each side. Once done, flip the frame over (taking care to hold everything together) and fasten the other side panel in place.

Y Axis

Bed Support Plate

Bearings

Requires:

- 4x LM8UU Linear Bearings

- 8x Cable Ties

- 1x Bed Support Plate

Sit the linear bearings in the cutouts on the bed support plate, and cable tie the bearings in place. Run one of the smooth rods through both sets of bearings to ensure that they are correctly aligned, and ensure the cable ties are fully tightened. Trim away the excess cable tie lengths.

Endstop Trigger

Requires:

- 1x M3x20mm Bolt

- 1x M3 Spring Washer

- 2x M3 Hex Nut

The Y endstop is positioned underneath the bed assembly. In order to actuate it, a bolt protrudes from the bottom of the support plate and makes contact with the switch. The position of the bolt can be changed to achieve different trigger points, which may be handy if you ever modify the printer. Install the bolt as shown in the hole third from the edge - this will allow for ~205mm of travel.

Belt Clamp

Requires:

- 2x Printed Y Belt Clamp

- 5x M3x20mm Bolt

- 4x M3 Spring Washer

- 5x M3 Hex Nut

Select one of the printed belt clamps, and install a bolt and nut as shown. This clamp will be used to tighten the y-axis belt later. The other printed clamp does not need the bolt and nut installed - it only clamps the opposite end of the belt in place. Fasten both clamps to the bed support plate as shown. For now, do not worry about tightening the bolts holding the clamps in place - they will need to be loosened and re-tightened later.

Y Motor

Bracket

Requires:

- 1x Y Motor Bracket

- 1x M3x20mm Bolt

- 1x M3 Spring Washer

- 1x M3 Hex Nut

Fix the motor mount in place as shown. Ensure the orientation is correct - the bottom of the acrylic part should be flat, while the top should have an angled cut towards the mounting tab.

Motor

Requires:

- 1x NEMA17 Motor

- 2x M3x15mm Bolt

- 2x M3 Spring Washer

- 1x GT2 Pulley

Insert the GT2 pulley onto the motor shaft, positioned as shown, and tighten the grub screws to hold it in place. Ensure one of the grub screws is directly over the flat of the motor shaft, in order to have the best grip possible.

Attach the motor to the bracket in the orientation shown.

Y Endstop

Bracket

Requires:

- 1x Y Endstop Bracket

- 1x M3x20mm Bolt

- 1x M3 Spring Washer

- 1x M3 Hex Nut

Fix the endstop bracket in place, ensuring that it points upwards as shown.

Endstop

Requires:

- 1x PCB Endstop

- 2x M3x10mm Bolt

- 2x M3 Spring Washer

- 2x M3 Hex Nut

- 2x 3mm Plastic Spacer

Mount the endstop to the bracket as shown.

Motor and Endstop Wiring

Y Idler

Assembly

Requires:

- 1x Printed Y Idler

- 2x 624ZZ Roller Bearing

- 1x M4x20mm Bolt

- 1x M4 Hex Nut

Assemble the Y Idler as shown. Ensure that the bearings can spin freely.

Installation

Requires:

- 1x Assembled Y Idler

- 2x M3x20mm Bolt

- 2x M3 Hex Nut

- 2x M3 Spring Washer

Attach the Y Idler to the inside of the front Y panel as shown.

Y Belt

Heated Bed

Wrap Wiring

Attach to Support Plate

Install Y Axis

Extruder Assembly (Single Extruder)

X Carriage

HotEnd

E3D have detailed instructions for assembling both the Lite6 and V6 HotEnds available online. Follow the instructions they provide, but don't yet insert the PTFE tubing or power up the HotEnd. Leave the fan separate for the time being.

Extruder

Fan

Z Probe

Requires:

- 1x IR Z Probe

- 2x M3 Plastic Spacers

- 2x M3x10mm Bolt

- 2x M3 Spring Washer

- 2x M3 Hex Nut

The Z Probe is designed to mount to the same hole pattern as is used by the 30mm HotEnd cooling fan. The recommended mounting location is on the opposite side of the X carriage from the fan, as shown. Alternatively, the probe can be mounted directly to the cooling fan if preferred - but the offset values in the firmware will need to be adjusted accordingly.

Wiring

- Spiral wrap

- Cable tie

Extruder Assembly (Dual Extruder)

X Carriage

HotEnd

E3D have detailed instructions for assembling both the Lite6 and V6 HotEnds available online. Follow the instructions they provide, but don't yet insert the PTFE tubing or power up the HotEnd. Leave the fan separate for the time being.

Extruder

Fans

Z Probe

Requires:

- 1x IR Z Probe

- 2x M3 Plastic Spacers

- 2x M3x10mm Bolt

- 2x M3 Spring Washer

- 2x M3 Hex Nut

The Z Probe is designed to mount to the same hole pattern as is used by the 30mm HotEnd cooling fan. The recommended mounting location is on top of the cooling fan on the right of the X carriage - in this orientation the cable will exit back towards the X carriage.

Wiring

- Spiral wrap

- Cable tie

X Axis

X Motor Assembly

Linear Bearing

Requires:

- 1x Printed X-Motor Part

- 1x LM8UU Linear Bearing

Insert the linear bearing as shown. It should be a firm fit - you may need to use a hammer to gently tap the bearing in place. If the bearing is slightly loose, it can be clamped in place using two bolts through the part as shown.

Carriage Nut

Requires:

- 4x M3x15mm Bolt

- 1x Leadscrew Carriage Nut

Insert the carriage nut, and fasten it in place as shown. The bolts should bite into the plastic of the printed part quite firmly.

Rod Tighteners

Requires:

- 2x M3x10mm Bolt

- 2x M3 Hex Nut

There is a nut trap inside each of the cylindrical cut-outs for the smooth-rods. Insert a nut into each one, oriented so that a bolt can pass through it through the hole in the printed part. If the nut is incorrectly oriented, try tapping the part gently - if you're lucky, the nut should tend towards being correctly oriented. If you're unlucky, you might need to remove the nut and drop try to place it again. Once in the correct orientation, screw the bolt into (but not yet extending out of) the nut, as shown.

Motor Pulley

Requires:

- 1x NEMA 17 Stepper Motor

- 1x GT2 Pulley

Install the GT2 pulley onto the stepper motor shaft, spaced as shown. Take care that one of the grub screws aligns with the flat of the motor shaft to ensure a good grip.

Motor Installation

Requires:

- 1x NEMA 17 Stepper Motor

- 3x M3x20mm Bolt

Fasten the stepper motor in place as shown. It is easier later to wire the motor with the cable connector oriented downwards.

Endstop

Requires:

- 1x PCB Endstop

- 2x M3x15mm Bolt

- 4x 3mm Plastic Spacer

Install the endstop as shown, taking care to orient it correctly.

X Idler Assembly

X Carriage Installation

Z Axis

Z Motors

Requires:

- 8x M3x15mm Bolt

- 8x M3 Spring Washer

- 2x NEMA17 Stepper Motors (34mm)

- 2x 8mm Couplers

Fix the Z motors in place as shown. Attach a flex coupler to each motor, with the motor shaft entering the smaller size of each coupler. Tighten the outer bolt to clamp the coupler in place, and then tighten the centre grub screw to ensure a secure fit.

Installing X Axis

Position the assembled X axis over the Z motors as shown. Lower the smooth rods through the top of the frame, through the linear bearings in the X axis and into the cutouts in the Z motor brackets. You may need to adjust the spacing between the X motor and X idler ends in order for the rod to fit smoothly.

Spool Holder

Requires:

- 1x 8mm Smooth-rod

- 2x Printed Spool Holder Adaptor

Press each end of the smooth-rod into the printed adaptors. Insert the assembly into the cut-out on the printer frame, as shown.

Additional Resources

- Exploded view of entire printer

- Exploded view of extruder assembly